Mechanical Horse Saddle Quilting Machine

The serial of economic quilting machines used for the garments , fashion handbags, kitchen sets ,aprons,oven gloves,potholders ,shoes covers ,outdoor sleeping bags etc. This serial of cam model quilting machine china now only our CHISHING company still produce it.

Classification:

Key words:

Product Description

Economic manual quilting machines

The serial of economic quilting machines used for the garments , fashion handbags, kitchen sets ,aprons,oven gloves,potholders ,shoes covers ,outdoor sleeping bags etc.

This serial of cam model quilting machine china now only our CHISHING company still produce it.

CS64 CS94 These competitive mechanical Multi-needle quilting machines come with following advantages:

1.quilting price is very cheap and competitive; small invest and profit quickly.

2.the machine size is small and save space .

Products Description :

1.The machine is easy in operation

2.180 degrees quilting

3.The pattern depends on the Cam model and different needle setting

4.Stitch length changed by the gears 7-9stitches per inch can be set.

CHISHING MACHINE ADVANTAGES

Machine base : In order to reduce vibration and deformation,

1.the machine bold reinforcement;

2.Casting annealing to reduce deformation and crack

The roller part:has carried on the special heat treatment to prevent deformation,

Needles and shuttles Part: CHISHING choose use West Germany needles and Imported HASHIMA shuttles.

Packing details:

1.Neutral packing or standard export wooden case packing can be optional.

The machines are tested and inspected carefully by QC before delivery .

2.Our company’s standard packing as the following :

Each part of the machine will be packed carefully by our workers .

3.Main major part will be oiled and will be packed by quilting sample and PE film .

Spare parts will be packed by plastic box

4. Other removing parts like thread frame and walkway and supporting parts will be packed by quilting sample and PE film .

Delivery time :

7-30days after receive the 30% deposit .

Warranty :

The machine come with One year guarantee and lifetime service

Payment term:

30% deposit and balance will be paid by T/T or Irrevocable L/C at sight

Technical Data:

| Function/ Parameters/ Model | CS64-2 | CS94-2 | CS94-3 |

| Dimension of main body (length * width * height) |

3150*960*1560mm | 4000*560*1600mm | 4300*1150*1650mm |

| Distance between needle bars or neele row pitch |

No.1-No.2 : 76.2mm | No.1-No.2 : 76.2mm | No.1-No.2: 76.2mm |

| No.1-No.3: 152.4mm | |||

| Needle spacing or needle pitch | 25.4mm | 25.4mm | 25.4mm |

| X saddle stroke | 101.6mm (4") | 203.2mm (4") | 304.8mm (6") |

| Quilting thickness | ≤30mm;400g/m2 | ≤30mm;400g/m2 | ≤30mm;400g/m2 |

| Stitch length | 2-6mm | 2-6mm | 2-6mm |

| Output | 20-120m/h | 20-120m/h | 20-120m/h |

| Needle model | #16,#19 | #16,#19 | #16,#19 |

| Maxim needle number | 128pcs | 188pcs | 282pcs |

| Quilting width | 1626mm | 2388mm | 2388mm |

| Rotating speed | 200-500 r/min | 200-500 r/min | 200-500 r/min |

| Rated power | 1.5 kW | 2.2 kW | 2.2kW |

| Voltage | 380v/50Hz | 380v/50 Hz | 380v/50Hz |

| 220V/60 Hz | 220V/60 Hz | 220V/60 Hz | |

| Overall weight | 1500kg | 2200kg | 2530kg |

Purchasing guide:

The needles and shuttles parts:

Choose which kind of needles depending on the sewing the material.For instance for processing fine or elastic materials or leather or thick materials, SCHMETZ offers a range of special needles including the SCHMETZ SERV 7,KN,SF and FHS.

CHISHING standard needles come with the machine is DUOTEC and if you make special materials then you need purchase

Different needles according to your products.

Shuttles parts: The quality of shuttles will direct effect the sewing quality and production efficiency. The poor quality shuttles will appear shrapnel lock is not tight, or bounce off and the thread waste, shuttle hot deformation cause skip stitches after use for some time.

CHISHING brand quilting machine insist use imported shuttles, For instance Japan and Swiss brand

Applications: Garments ,winter-jackets, bedding covers ,mattress ,mattress protectors ,sofa protectors ,oven gloves ,

Winter wear pajamas, shoes pad, hand bags, wall decorations ,car cushions, prayer pad, summer quilts ,blankets etc

The difference between HQ7 and HQ10

HQ7 shuttle can hold 60meter thread(50/2 40/2 thread)

HQ10shuttle can hold 90meter thread(50/2 40/2 thread)

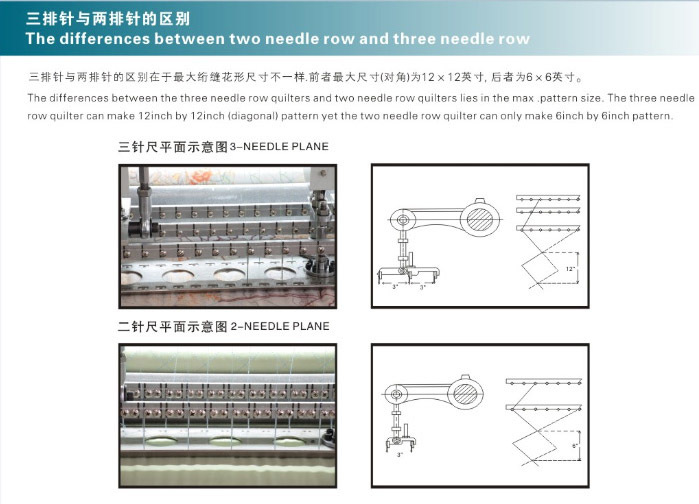

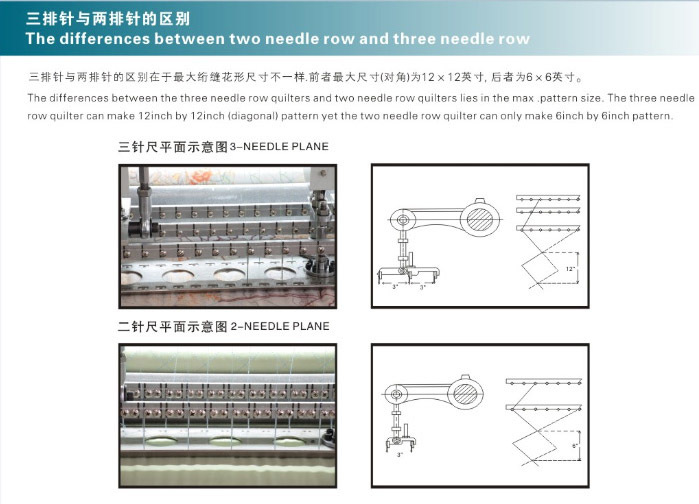

The difference between 2 needle bar and 3 needle bar

2 needle bar machine the Max. Pattern size is 6inch by 6inch

3 needle bar machine the Max. Pattern size is 12inch by12 inch (use NO.1 and NO.3 needle row)

MAINTANENCE:

Quilting machine structure to can be divided into the following 4 major parts:

a.Machine major part

b.needle part

c.shuttle part

d.Circuit part

1. According to the lubrication circuit correct lubrication machine

2. Before the machine, check all bolts, screws are tight

3. As far as possible do check once a month all machine parts if there is a fault

4. If you find a place fails, debugging before the repair can't boot up

5. Because of careless or failure, should pay attention to check whether there are objects on the running machine

Installed schematic

FINISHED PRODUCTS SHOW:

give us message

We are very willing to listen to your message, if you have any questions about Zhicheng Machinery products or need to provide service support

Please fill out the following form and we will contact you as soon as possible

0086-131-2940-3844

0086-131-2940-3844 sales@quiltingmachine.cn

sales@quiltingmachine.cn