64 inches computerized multi needle quilting machine

Classification:

Key words:

Product Description

The serial of economic quilting machines used for the garments , car mat, car cushions protectors ,handbags, oven gloves and shoes covers ,outdoor sleeping bags etc.

CS64 -2 These competitive quilting machines come with following advantages:

1.quilting price is very cheap and competitive; small invest and profit quickly.

2.the machine size is small and save space .

Products Description :

Digital control shuttle multi-needle quilting machine has following features:

1.This quilting machine adopting digital control program.

2.Saddles and Rollers driven by Panasonic servo devices..

3.The revolution of the spindle controlled by Panasonic frequency control devices.

4.360 degrees quilting machine come with 300quilting patterns for your choice.

5.Easy pattern drawing system enable you finish the pattern design in a few minutes.

6.Tack and jump function included

7.Stitches length 2mm-6mm adjustable.

8.Function of Pattern compensation and effective solution to the distortion of patterns

9. Adjustable pressing plate lifting mechanism enables you quilt a broad range of material thickness

10.Automatic thread break detectors for the top thread.

11.Automatic needle raising and location brake system

12. With Error alarm system

13.Emergency sensors safety device

14.Improved quilting software control system allows more precise and stable quilting operations

15.Improved fabric loading system:The fabric-loading motor ensure tension control and the quilting effect.

CHISHING MACHINE ADVANTAGES

Machine base : In order to reduce vibration and deformation,

1.the machine bold reinforcement;

2.Casting annealing to reduce deformation and crack

The roller part:has carried on the special heat treatment to prevent deformation,

Driving Part: servo motor, Drivers and Transducer are Panasonic brand

Raw Materials Feeding Part: adopt unique adjustable roller active-feeding system, With the different thickness of material, the Tension and pressure can be adjusted ideally which can ensure the quilting effect is perfect no skip stitch and it will not damage the fabric.

Needles and shuttles Part: Chishing choose use West Germany needles and Imported HASHIMA shuttles.

Packing details:

Neutral packing or standard export wooden case packing can be choosen.

The machines are tested and inspected carefully by QC before delivery .

Our company’s standard packing as the following :

Each part of the machine will be packed carefully by our workers .

Main major part will be oiled and will be packed by quilting sample and PE film .

Computer and monitor will be packed by EPE foam and cartons

Spare parts will be packed by plastic box

Other removeing parts like thread frame and wakway and supporing parts will be packed by quilting sample and PE film .

Delivery time :

7-30days after receive the 30% deposit .

Warranty :

The machine come with One year guarantee and lifetime service

Payment term:

30% deposit and balance will be paid by T/T.

TECHNICIAL DATA

| Function / Parameter /Model | CS64-2 |

| Dimension(L*W*H) | 3600*1100*1600mm |

| Needle row distance | No.1-No.2 : 76.2mm |

| Needle distance | 25.4mm |

| Carrage stroke | 152.4mm(6") |

| Max.thickness | ≤30mm |

| Stitch Length | 2-6mm |

| Output | 20-120m/h |

| Needle No. | #16,#19 |

| Max Quantity of Needles | 128pcs |

| Quilting width | 1626 mm |

| Rotating Speed | 200-500RPM |

| Rated Power | 3.5kW |

| Voltage | 380V/50 Hz 220V/60 Hz |

| Weight | 2300kg |

Purchasing guide

The needles and shuttles parts:

Choose which kind of needles depending on the sewing the material.For instance for processing fine or elastic materials or leather or thick materials, SCHMETZ offers a range of special needles including the SCHMETZ SERV 7,KN,SF and FHS.

Chishng standard needles come with the macine is DUOTEC and if you make special materials then you need purchase

Different needles according to your products.

Shuttles parts: The quality of shuttles will direct effect the sewing quality and production efficiency. The poor quality shuttles will appear shrapnel lock is not tight, or bounce off and the thread waste, shuttle hot deformation cause skip stitches after use for some time.

CHISHING brand quilting machine insist use imported shuttles, For instance Japan and Swiss brand

Applications: Garments ,winter-jackets, bedding covers ,mattress ,mattress protectors ,sofa protectors ,oven gloves ,

Winter wear pajamas, shoes pad, hand bags, wall decorations ,car cushions, prayer pad, summer quilts ,blankets etc

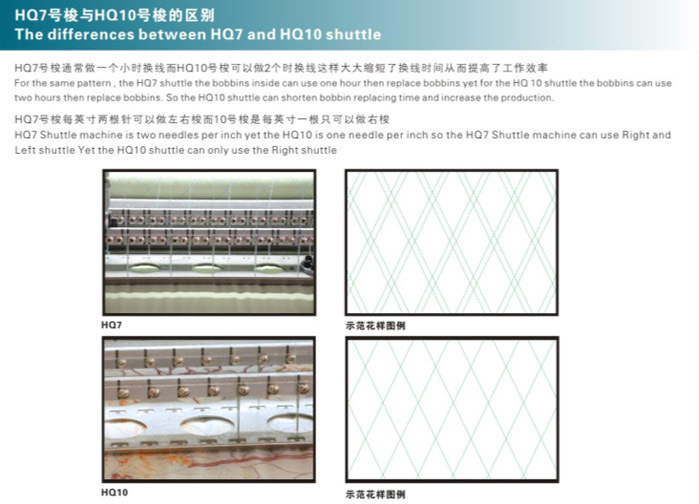

The difference between HQ7 and HQ10

HQ7 shuttle can hold 60meter thread(50/2 40/2 thread)

HQ10shuttle can hold 90meter thread(50/2 40/2 thread)

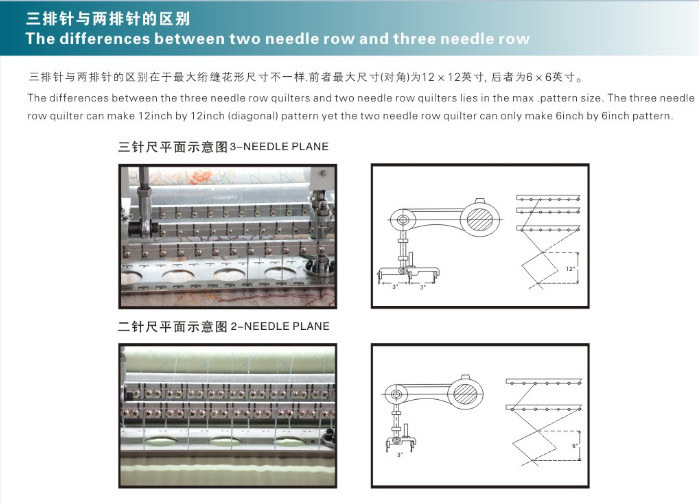

The difference between 2 needle bar and 3 needle bar

2 needle bar machine the Max. Pattern size is 6inch by 6inch

3 needle bar machine the Max. Pattern size is 12inch by12 inch (use NO.1 and NO.3 needle row)

give us message

We are very willing to listen to your message, if you have any questions about Zhicheng Machinery products or need to provide service support

Please fill out the following form and we will contact you as soon as possible

0086-131-2940-3844

0086-131-2940-3844 sales@quiltingmachine.cn

sales@quiltingmachine.cn