Maintenance knowledge of Low price Computerized Quilting and Embroidering Machine

Release time:

2022-04-18 15:42

Source:

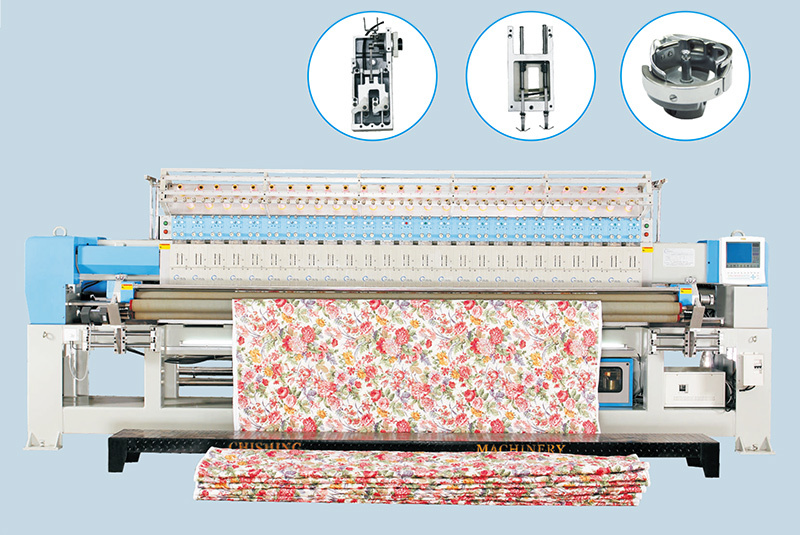

Compared with traditional quilting and embroidery equipment, the Low price Computerized Quilting and Embroidering Machine has more complete functions and configurations. All its patterns and programs are stored on the computer hard disk, abandoning the traditional quilting and embroidery machine that relies on worker patterns for design. This design allows people to complete the design of the pattern only by operating the computer. At the same time, the computer displays the preset parameters, quilting and quilting patterns and working status in Chinese. People only need to press the on-screen menu prompts and select the required working parameters during operation, and then the product can be manufactured. So how to maintain the Low price Computerized Quilting and Embroidering Machine?

Low price Computerized Quilting and Embroidering Machine power supply grounding wire must be grounded independently, and must not be mixed with the "zero" wire in the power supply; to ensure the stability of the input voltage, if necessary, a voltage stabilizer can be configured to ensure the normal electrical components of the machine Operation, Low price Computerized Quilting and Embroidering Machine computer parts and frequency converters should not be opened at will. If there is any fault in this area, please contact the manufacturer in time, and the manufacturer or its agent will send someone to repair it. When pulling out or installing the clamping frame When the machine is running, check whether the needle is in a relatively high position to avoid pulling the fabric; all belts on the machine must not be oiled. If oil is found on the surface of the belt, it should be wiped clean in time.

Secondly, before using the Low price Computerized Quilting and Embroidering Machine, the quilting embroidery head should be cleaned and oiled, because the head will not be oiled when it leaves the factory. Moreover, there is a leakage protector when working, and it is suitable for the voltage and power required by the computerized quilting and embroidery machine. It must have a reliable grounding, and the frequency converter and the host grounding are separated. In the event of a power failure or power failure during the operation of the Low price Computerized Quilting and Embroidering Machine, or when there is a problem with the quilting and embroidery machine (needle or thread), we should immediately stop the machine for repair and maintenance.

Related news

During the "Eleventh Five-Year Plan" period (2006-2010), China took industrial energy conservation, consumption reduction, emission reduction and pollution control as an important measure to adjust the industrial structure and transform the development mode, and promoted industrial energy conservation to continuously achieve substantial results. At the same time, China's industrial energy conservation and emission reduction are still facing severe challenges.

Exploring the Mechanics Behind High-Speed Quilting Machines: A Comprehensive Guide

Exploring the Mechanics Behind High-Speed Quilting Machines Table of Contents Introduction to High-Speed Quilting Machines The Importance of High-Speed Quilting in the Textile Industry Key Components of High-Speed Quilting Machines How High-Speed Quilting Machines Work Advanced Technologies in High-Speed Quilting Machines Choosing the Right High-Speed Quilting Machine for

The Essential Guide to Quilting Embroidery Machines for Professional Use

Quilting embroidery machines are specialized tools designed for the intricate task of combining quilting and embroidery techniques, offering a wealth of opportunities for professionals in the apparel and textile industry. These machines allow users to create complex designs, patterns, and textures that can transform a simple piece of fabric into a work of art. Understanding the capabilities and fu

Why CS64 Digital Control Machines are Essential for Modern Clothing Production

Why CS64 Digital Control Machines are Essential for Modern Clothing Production Introduction to CS64 Digital Control Machines In the fast-paced world of fashion, where trends shift rapidly and consumer demands fluctuate, the efficiency of clothing production is paramount. The advent of CS64 Digital Control Machines has revolutionized the manufacturing landscape, offering unparalleled precision and

Maximizing Efficiency in Bedspread Manufacturing with 2.4 Meters Quilting Machines

In the competitive world of textile manufacturing, particularly in the production of bedspreads, choosing the right machinery is crucial for operational success. A 2.4 meters bedspreads quilting machine stands out as an essential tool for manufacturers looking to enhance their production capabilities. This machine, specifically designed for quilting, offers various benefits that can significantly

The Advantages of Using Multi Needle Quilting Machines Like CS128

The Advantages of Using Multi Needle Quilting Machines Like CS128 Introduction to Multi Needle Quilting Machines In the world of sewing and quilting, technology continually evolves to meet the growing demands of creativity and efficiency. **Multi needle quilting machines**, particularly models like the **CS128**, have emerged as a game-changer for both amateur and professional quilters alike. Thes

0086-131-2940-3844

0086-131-2940-3844 sales@quiltingmachine.cn

sales@quiltingmachine.cn